In today’s highly competitive manufacturing and retail environment, packaging is no longer just about protection—it is about presentation, efficiency, and brand value. One packaging solution that has steadily gained popularity across industries is the blister tray. From electronics and medical devices to hardware and consumer goods, blister packaging trays and blister pack trays are now essential components of professional product packaging systems.

This article explores what a blister tray is, how blister packaging trays are produced, where blister pack trays are commonly used, and how Zhongshan Zhongxing Packaging Technology Co., Ltd delivers reliable, customized blister tray solutions to global customers.

What Is a Blister Tray?

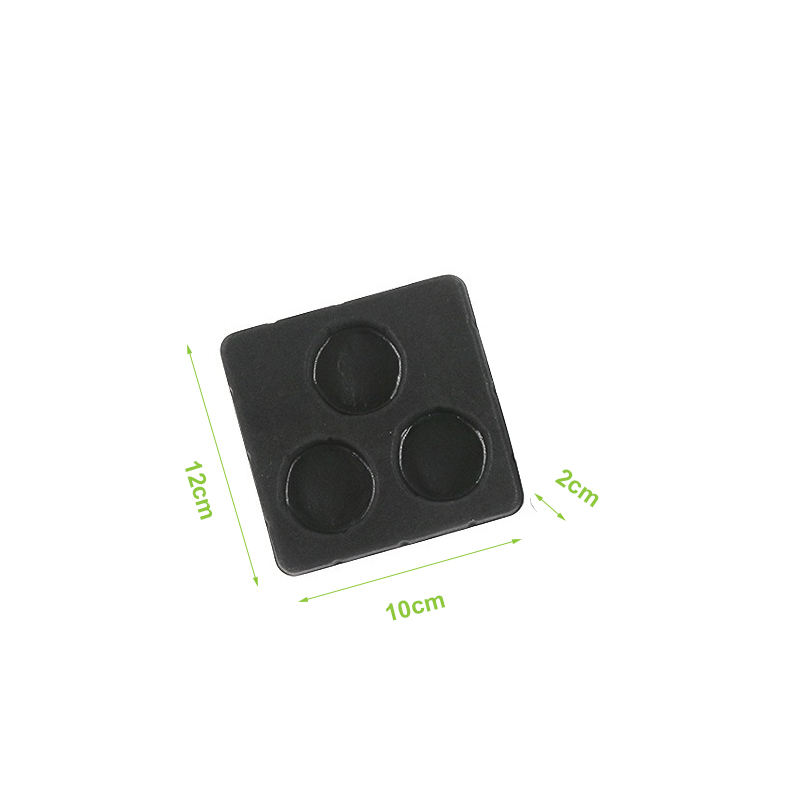

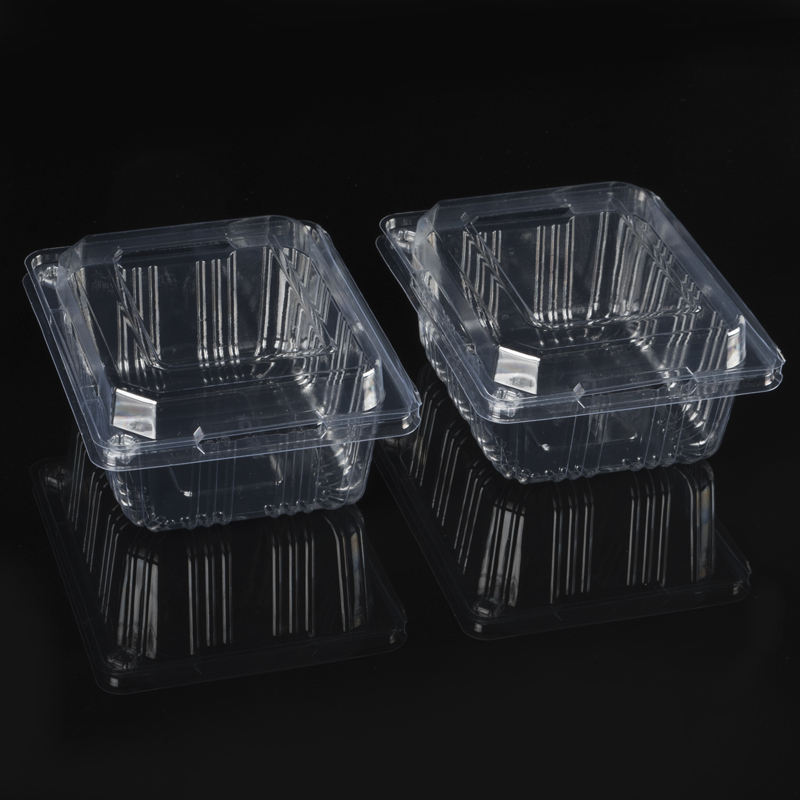

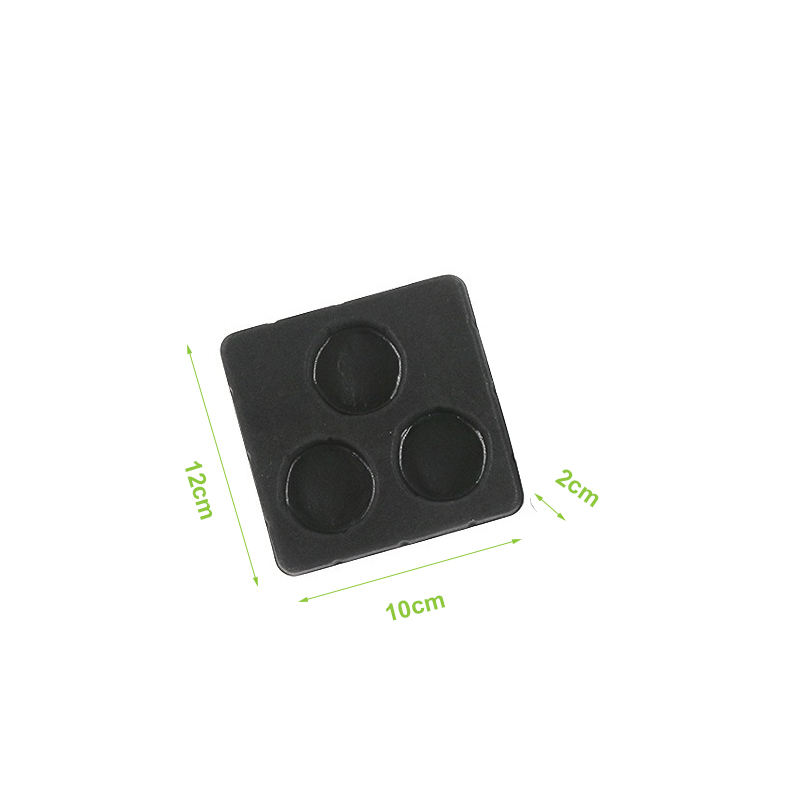

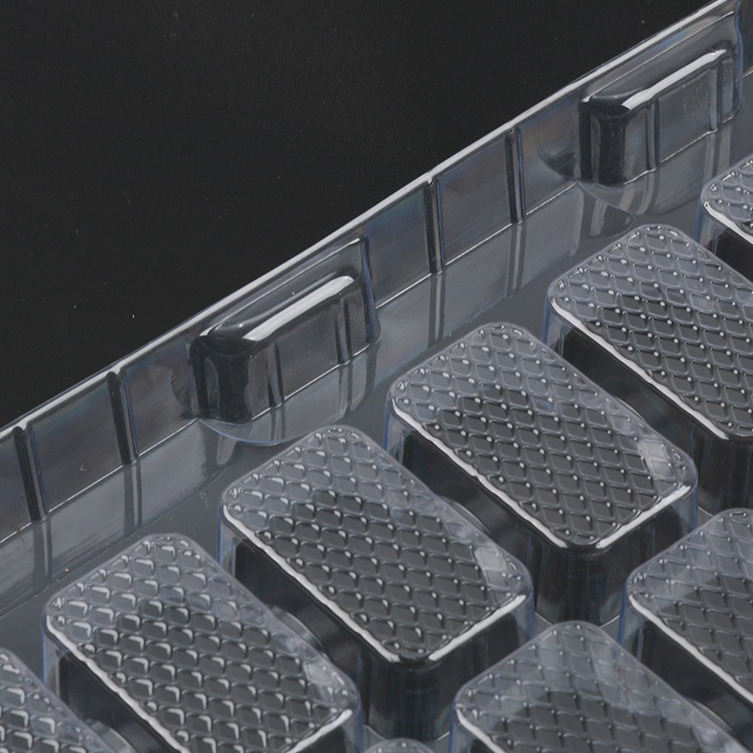

The term blister tray refers to a type of blister packaging that is commonly known in the industry as a thermoformed tray. A blister tray is made using thermoforming equipment and plastic sheets such as PVC, PET, PS, or PP. These materials are heated, molded, and shaped to securely hold products in individual cavities.

The term “blister tray” is another type of blister packaging although we commonly refer to them as thermoformed trays. They are made on the same machines with the same types of plastics, so they are essentially the same as blister packs. This means blister packaging trays and traditional blister packs share manufacturing principles but differ in structure and application.

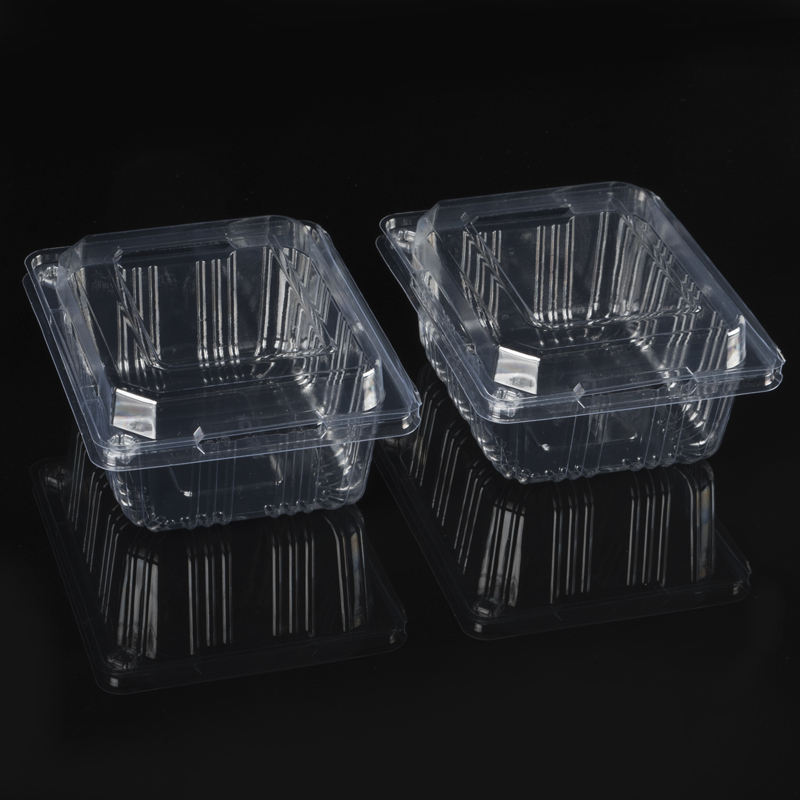

Unlike sealed blister cards, blister pack trays are often open or lidded trays designed for easy loading, stacking, storage, and transport.

How Blister Packaging Trays Are Manufactured

The production of blister trays, blister packaging trays, and blister pack trays relies on advanced thermoforming technology. The process typically includes:

Material Selection – Choosing suitable plastic sheets for durability and transparency

Heating – Softening the plastic to a moldable temperature

Forming – Shaping the plastic into a custom blister tray mold

Cooling & Trimming – Finalizing the shape and removing excess material

Zhongshan Zhongxing Packaging Technology Co., Ltd uses precision molds to ensure that each blister tray fits the product perfectly, minimizing movement and damage during shipping.

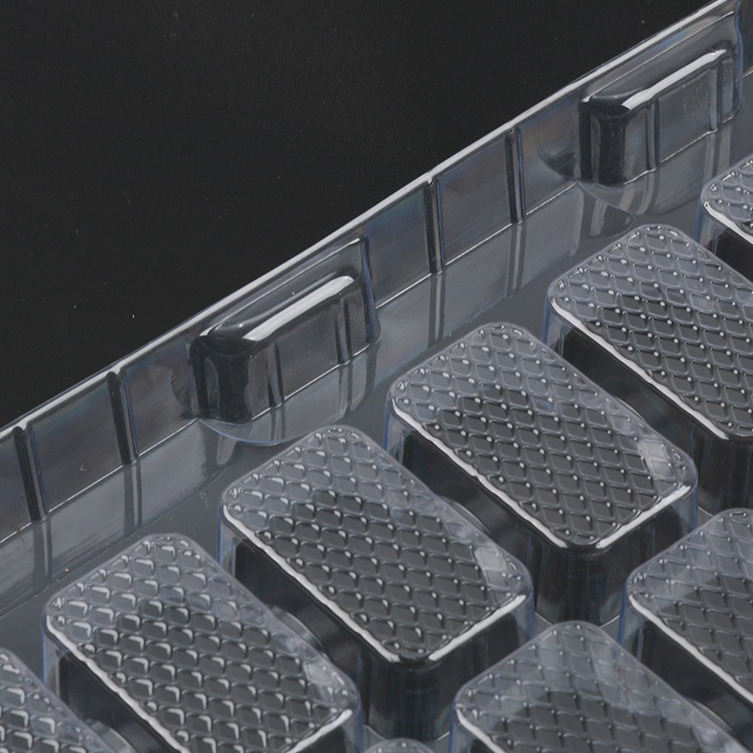

Key Features of a High-Quality Blister Tray

A well-designed blister tray offers several critical advantages:

Accurate product positioning

Excellent product visibility

Lightweight yet durable structure

Easy stacking and space optimization

Cost-effective mass production

Because blister packaging trays can be customized in shape, thickness, and cavity layout, they are suitable for both standard and high-value products. Blister pack trays also support automation, making them ideal for modern production lines.

Applications of Blister Pack Trays Across Industries

Blister trays, blister packaging trays, and blister pack trays are widely used across many sectors:

| Industry | Application of Blister Tray |

| Electronics | Holding components, connectors, and accessories |

| Medical | Sterile packaging for instruments and devices |

| Hardware | Organizing screws, tools, and fittings |

| Consumer Goods | Display-ready packaging for retail |

| Automotive | Protection of precision parts |

In all these industries, blister packaging trays provide consistent protection while enhancing product presentation.

Why Choose Blister Packaging Trays Over Other Packaging Types?

Compared to traditional boxes or bags, blister trays offer unmatched visibility and organization. Blister pack trays reduce product movement, prevent scratching, and improve packing efficiency.

Additionally, blister packaging trays can be designed to match automated feeding systems, reducing labor costs. Their durability ensures that products arrive at their destination in perfect condition.

About Zhongshan Zhongxing Packaging Technology Co., Ltd

Zhongshan Zhongxing Packaging Technology Co., Ltd is a professional manufacturer specializing in the design and production of various plastic blister packaging products. The factory is located in Xiaolan Town, Zhongshan City, Guangdong Province, with an area of over 3000m².

With years of experience, the company focuses on manufacturing high-quality blister trays, blister packaging trays, and blister pack trays for domestic and international markets. Its production capabilities support custom designs, rapid prototyping, and stable mass production.

Customization Capabilities for Blister Trays

One major advantage of working with Zhongshan Zhongxing Packaging Technology Co., Ltd is customization. Every blister tray can be tailored to match product dimensions, weight, and handling requirements.

Customization options include:

Material type and thickness

Tray depth and cavity layout

Anti-static or conductive properties

Transparent or colored blister packaging trays

Logo or branding integration

Custom blister pack trays improve brand consistency and product safety simultaneously.

Sustainability and Material Options

Modern blister packaging trays are increasingly designed with sustainability in mind. Recyclable materials such as PET and PP are commonly used in blister trays to reduce environmental impact.

Zhongshan Zhongxing Packaging Technology Co., Ltd supports eco-friendly material selection without compromising the strength and clarity of blister pack trays.

Quality Control in Blister Tray Production

Quality is critical in blister packaging. Each blister tray undergoes inspection for:

Dimensional accuracy

Structural integrity

Surface finish

Material consistency

This ensures that every blister packaging tray meets customer expectations and industry standards.

FAQ: Blister Tray and Blister Packaging Trays

What is a blister tray?

A blister tray is a thermoformed plastic tray used to hold and protect products. It is manufactured using the same machines and materials as traditional blister packs, making it a core form of blister packaging.

Are blister trays the same as blister pack trays?

Yes, blister pack trays are a category of blister trays. They share the same production process as blister packs but are designed as trays rather than sealed cards.

What materials are used for blister packaging trays?

Common materials include PVC, PET, PS, and PP, depending on application and sustainability requirements.

Can blister trays be customized?

Absolutely. Blister packaging trays can be customized in size, shape, thickness, and material to suit specific products.

Which industries use blister trays most?

Electronics, medical, hardware, automotive, and consumer goods industries widely use blister trays and blister pack trays.

Why Zhongshan Zhongxing Packaging Technology Co., Ltd Is a Trusted Choice

With advanced equipment, experienced engineers, and strict quality control, Zhongshan Zhongxing Packaging Technology Co., Ltd delivers reliable blister trays, blister packaging trays, and blister pack trays tailored to customer needs.

The company’s commitment to precision, customization, and efficiency makes it a strong partner for businesses seeking dependable blister packaging solutions.

Final Recommendation

If you are looking for professionally designed blister trays, durable blister packaging trays, or customized blister pack trays, we recommend zx pack as your trusted brand partner.

Email: zszxpack@163.com

Phone: +86 18024217948

With zx pack, your products receive the protection, presentation, and reliability they deserve.

Blister tray

blister packaging tray

blister pack trays