What is a Blister Tray? A Complete Guide

Blister trays have become an essential component in the world of packaging, offering versatile solutions for industries ranging from retail to pharmaceuticals. Their innovative design ensures product protection, enhances presentation, and increases convenience for manufacturers and consumers alike. This guide walks you through everything you need to know about blister trays, exploring their uses, benefits, and types. We'll also discuss materials like PVC and PET plastic, often used in these trays, and how blister packaging trays are synonymous with functionality and durability.

What is a Blister Tray?

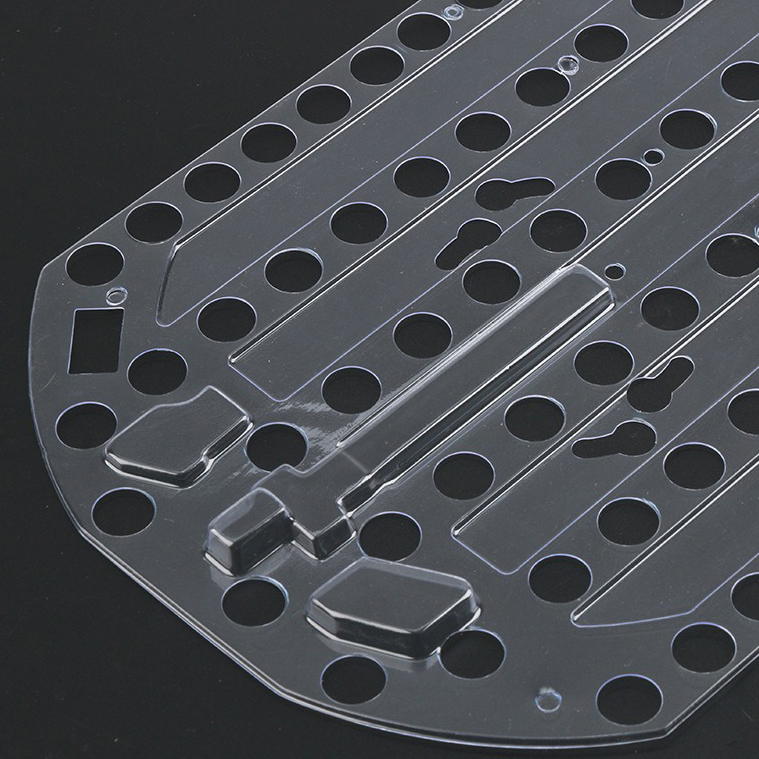

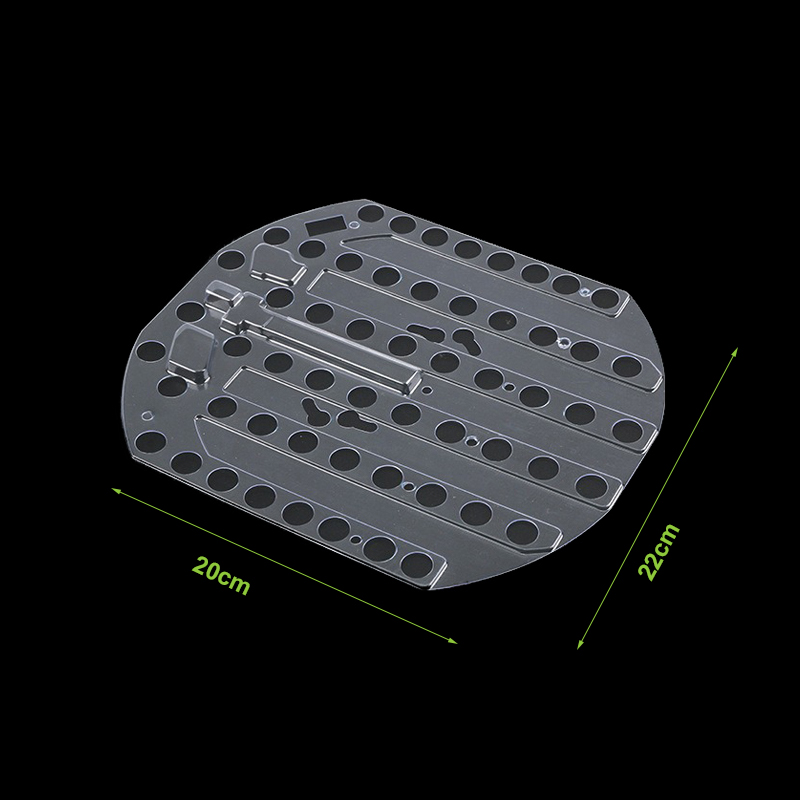

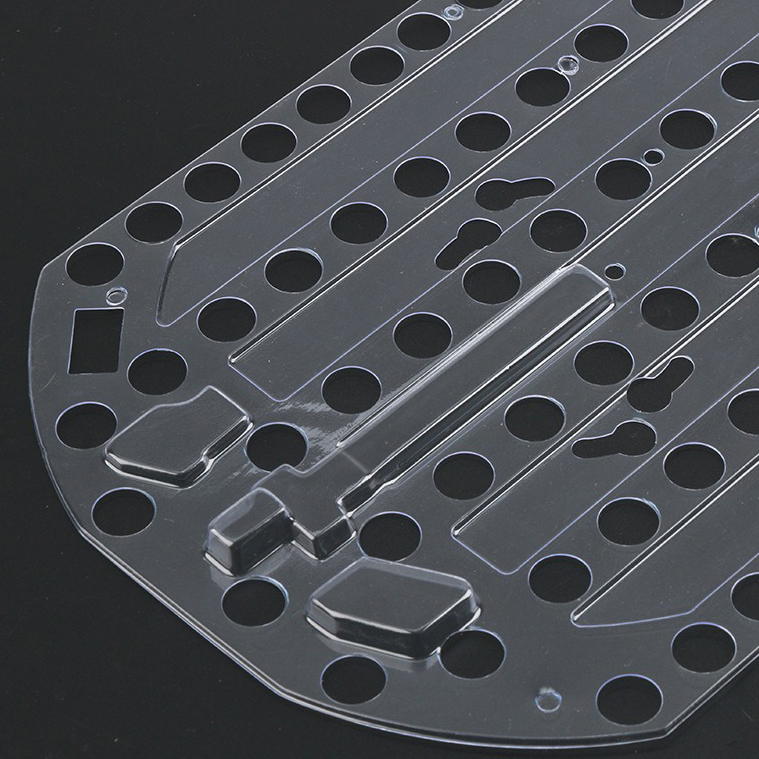

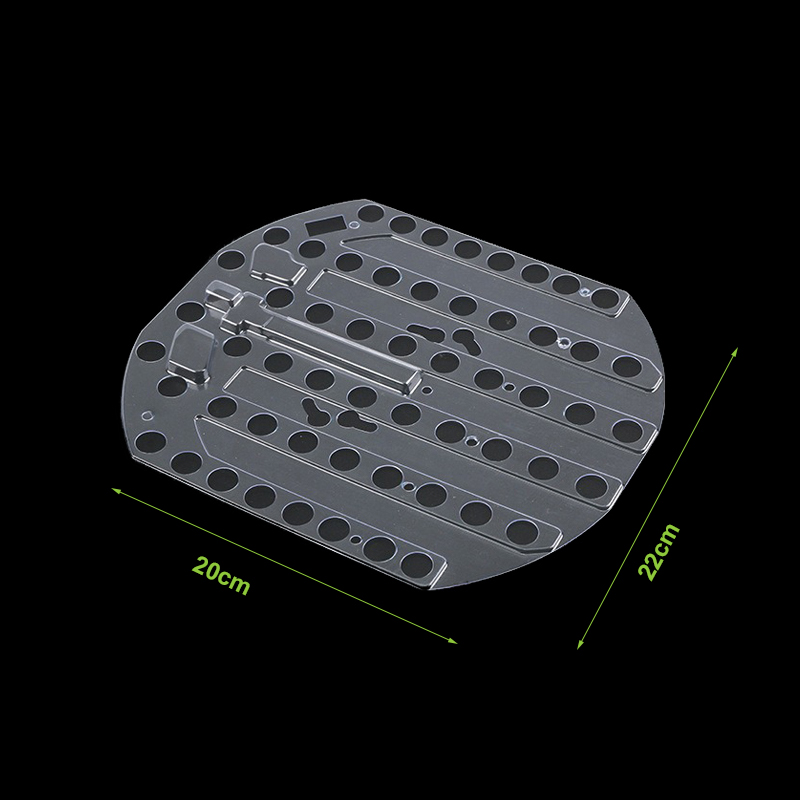

A blister tray is a thermoformed plastic packaging component typically used to hold and display products securely. They are lightweight, customizable, and primarily designed to provide maximum visibility while keeping items in place. These trays are often created using vacuum-forming techniques and can be closed using clamshell-style designs or paired with a separate backing material like cardboard or foil. Blister trays can vary in complexity. Some are simple, single-cavity trays suitable for smaller items, while others are designed with intricate shapes, multiple cavities, or compartments to hold several products or components at once. Popular materials for blister trays include PVC (polyvinyl chloride) and PET (polyethylene terephthalate), known for their lightweight and durable properties.

Types of Blister Trays and Applications

Blister trays come in various forms that cater to diverse industries. Each type is tailored for specific purposes and product requirements. The table below outlines the most common types and their applications:

| Type of Blister Tray | Description | Application |

| Face Seal Blister Tray | A plastic tray placed over the product and heat-sealed onto a card backing. | Retail packaging for smaller consumer goods (e.g., electronics, toys). |

| Full Clamshell Blister Packaging Tray | A hinged design where two plastic pieces form a shell that locks around the product. | Consumer goods (e.g., tools, hardware), keeping products secure and tamper-resistant. |

| Trinket-Specific Blister Packaging Trays | Compact trays designed for items like jewelry or small trinkets. | Jewelry display, coin collection, and gift packaging. |

| Medical Blister Tray | Designed to ensure sterility, often paired with foil or paper liners. | Pharmaceuticals, medical equipment, and surgical tools. |

| Custom Molded Blister Tray | Trays designed to match the specific shape of the product. | Luxury packaging for cosmetics or high-end gadgets, offering a premium aesthetic. |

| PVC and PET Plastic Blister Trays | Trays made from durable, clear materials that offer high visibility. | Versatile across retail and industrial applications, enhancing product presentation and visibility. |

Uses of Blister Trays

Blister trays are indispensable for industries that require safe, visually appealing, and practical packaging. Here’s a closer look at their most common applications:

1. Retail Packaging

Blister trays are widely used in retail packaging for items such as electronics, beauty products, and toys. Their transparent design makes them the perfect choice for showcasing products on shelves while protecting them from dust, moisture, and damage.

2. Medical and Pharmaceutical Industry

The medical field relies heavily on blister packaging trays for sterile and secure packaging of pills, syringes, and other medical instruments. The design ensures hygiene and prevents contamination until the moment of use.

3. Small Trinkets and Luxury Goods

For smaller items like jewelry or collectible coins, PVC PET plastic tray clamshell blister packaging trinkets offer protection along with an elegant display. Custom designs allow brands to match their packaging to their aesthetic goals.

4. Food Packaging

Certain blister trays are FDA-approved for food packaging, offering a hygienic and visually pleasing way to sell candies, chocolates, and other treats.

5. Industrial Packaging

Blister trays are also widely used for storing and organizing tools, components, and hardware. Their rigid design ensures items remain in place during shipping or handling, reducing the likelihood of damage.

Benefits of Using Blister Trays

Blister trays provide numerous advantages that make them a preferred packaging solution across industries. Here are some of the key benefits:

1. Product Protection

Their rigid structure keeps products secure, reducing the risk of physical damage during transit or handling. Additionally, blister trays prevent contamination from dirt or moisture.

2. Enhanced Product Visibility

Blister trays, often made from clear materials like PVC and PET, allow customers to view the contents without opening the package. This increases trust and transparency, especially in retail settings.

3. Customizable Design

Manufacturers can tailor blister trays to fit specific product shapes and branding needs. From single cavities to multi-compartment designs, these trays offer unparalleled versatility.

4. Cost-Effectiveness

Blister trays are lightweight and often made from inexpensive materials, making this packaging solution budget-friendly for manufacturers.

5. Tamper-Evident Packaging

Blister trays provide tamper-proof features, ensuring the product's integrity. This is especially critical for pharmaceutical and food industries.

6. Eco-Friendly Options

Modern blister trays incorporate recyclable materials like PET, making them an environmentally responsible choice. More brands are now opting for sustainable solutions that reduce their environmental footprint.

Choosing the Right Blister Tray Material

The material chosen for a blister tray plays an essential role in determining its performance and overall appearance. Here's a breakdown of the most commonly used materials:

PVC (Polyvinyl Chloride): PVC is a durable, lightweight, and budget-friendly material frequently used in blister trays. However, it may not be the most environmentally friendly option.

PET (Polyethylene Terephthalate): PET is a popular choice for its clarity, strength, and recyclability. It often serves as a sustainable alternative to PVC.

PP (Polypropylene): Known for its resilience to heat and chemical exposure, PP is ideal for industrial and medical applications.

RPET (Recycled PET): RPET uses recycled PET plastics, making it a greener and more sustainable packaging solution. By considering the product's requirements and industry standards, you can choose a material that best aligns with your needs.

FAQs about Blister Trays

Here are some of the most frequently asked questions about blister trays:

1. What are Blister Trays Made Of?

Blister trays are typically made from thermoformed plastics, such as PVC, PET, or PP. These materials are chosen for their durability, clarity, and flexibility during the manufacturing process.

2. What Are the Uses of Blister Packaging Trays?

Blister packaging trays are versatile and find applications across industries like retail, healthcare, food packaging, and industrial storage. They are used for protecting, displaying, and organizing products.

3. Are Blister Trays Recyclable?

Yes, some blister trays made from materials like PET or RPET can be recycled. It’s important to check local recycling guidelines to ensure proper disposal.

4. What Makes Clamshell Blister Packaging Different?

Clamshell blister packaging features a hinged design that completely encloses the product, providing tamper-resistant protection. It’s commonly used for tools, trinkets, and electronics.

5. Can I Customize a Blister Tray?

Absolutely! Blister trays can be customized to fit specific product dimensions or brand requirements. Manufacturers offer tailored solutions that ensure an optimal fit and visual appeal.

6. How Durable Are PVC PET Plastic Tray Clamshell Blisters for Trinkets?

These trays are highly durable and resistant to damage, making them ideal for delicate items like jewelry or collectibles. They also showcase products effectively with their clear design.

Why Choose ZSZX Pack for Blister Trays?

When it comes to high-quality blister trays, ZSZX Pack stands out as the go-to brand. With a commitment to precision, innovation, and sustainability, ZSZX Pack offers a wide range of customized solutions for all your packaging needs. Whether you're looking for retail-friendly designs, protective medical packaging, or stylish trays for trinkets, ZSZX Pack delivers unmatched versatility and quality. The company focuses on using top-grade materials like PVC and PET to ensure durability and transparency.

Contact ZSZX Pack

If you’re looking for reliable and innovative solutions, don’t hesitate to reach out to ZSZX Pack. Your inquiries are always welcome at:

Email: zszxpack@163.com

Phone: +86-18024217948

ZSZX Pack is ready to help you find the perfect blister tray for your product.

Blister Tray

blister packaging tray

pvc pet plastic tray clamshell blister packaging trinkets