Blister trays are a popular choice in the manufacturing and retail industries due to their practicality, durability, and cost-effectiveness. These packaging solutions are widely used across various sectors, including pharmaceuticals, electronics, and consumer goods. This article will provide a comprehensive overview of blister trays, discuss their benefits, and answer common questions, such as "What is blister packaging used for?" Read on to explore how blister packaging works and why it remains an essential component in product packaging.

What Are Blister Trays?

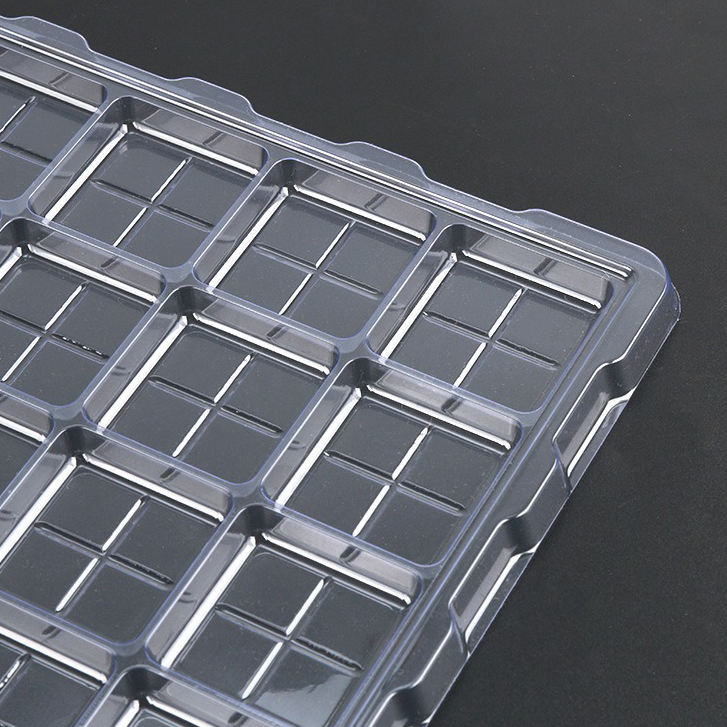

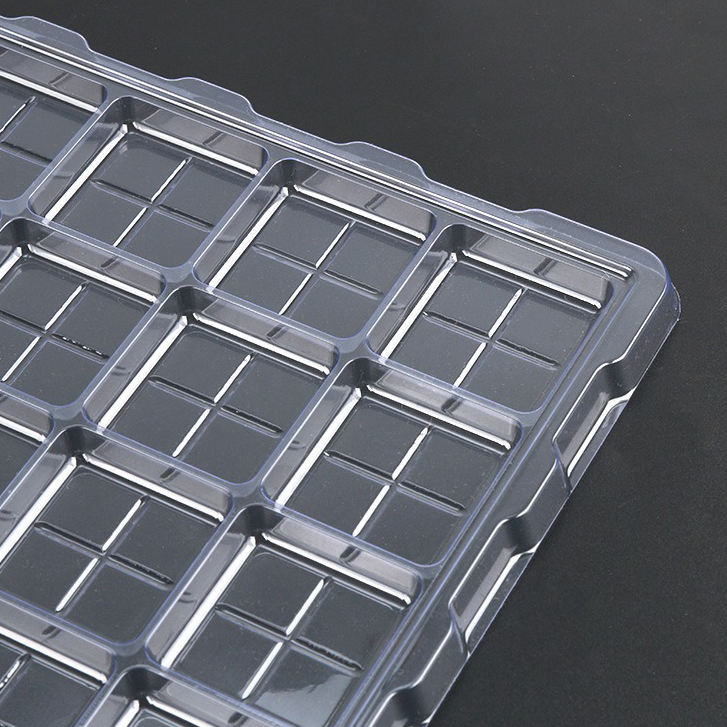

A blister tray is a type of packaging consisting of a pre-formed plastic cavity or pocket, sealed to a backing material such as aluminum foil, cardboard, or plastic film. These trays provide a protective enclosure for the packaged products, ensuring safety during storage, transportation, and display.

Blister trays are valued for their clarity, allowing customers to see the product before purchase. They're also easy to customize, environmentally friendly (when made from recyclable materials), and highly protective against environmental factors like moisture, dust, and contamination.

Here’s an example of the components of a typical blister packaging tray

Component | Description |

Plastic Cavity | Holds the product securely with its shape molded to the item's dimensions. |

Back Layer | Sealed to the plastic cavity for protection; often made of cardboard, foil, or plastic. |

Heat Seal or Clasp | Ensures the cavity and back layer stay airtight and tamper-proof. |

Blister trays can vary in terms of size, material, and customization, making them a versatile choice for businesses. |

|

Common Uses of Blister Packaging

Blister trays and blister packaging trays are extensively used across industries. Some of their most common applications include:

1. Pharmaceuticals

One of the most recognizable uses of blister packaging trays is in the storage and distribution of medications such as pills, capsules, and tablets. The packaging ensures these products are kept safe from contaminants and moisture while providing tamper evidence.

2. Electronics

Blister trays are often used to package small electronics like cables, headphones, and adaptors. The clear plastic ensures visibility, while the sturdy structure protects the products during transit and shelving.

3. Consumer Goods

From batteries to toy cars and personal care items, blister packaging trays are heavily used in the retail sector for their ability to showcase items while also keeping them secure.

4. Food Industry

Blister packaging extends into foods, too, such as chocolates, chewing gum, and snacks. The protective layers ensure freshness and quality after packaging.

Advantages of Using Blister Trays

Opting for blister trays offers several benefits for manufacturers and retailers:

Product Visibility

Consumers can easily view the product inside a transparent blister tray, boosting trust and appeal.

Durable Protection

The sturdy plastic structure safeguards products from breakage, dirt, and tampering.

Easy Customization

blister pack trays can be designed to precisely fit the shape and dimensions of the product, enhancing both safety and aesthetics.

Cost Efficiency

Due to their lightweight and minimal material requirements, blister trays are cost-effective compared to other forms of packaging.

Sustainability

Many blister trays are made from recyclable or biodegradable materials, making them eco-friendly without compromising quality.

FAQ Section

What is blister packaging used for?

Blister packaging is commonly used for small items like batteries, medicines, and toy cars. It provides a secure and visually appealing method of displaying and storing products. The plastic front protects the contents from exposure to moisture and contaminants, while the backing (typically cardboard or foil) serves as a sturdy seal. Depending on the application, additional features like tamper-evident seals and perforated layers are also included to enhance functionality.

Unlike regular packaging, blister trays are particularly beneficial in ensuring that high-value or sensitive products, such as pharmaceuticals and electronics, remain in peak condition from production to delivery.

What materials are used in blister trays?

Blister trays are primarily made using PVC (polyvinyl chloride) or PET (polyethylene terephthalate) for the plastic cavity. These materials are chosen for their clarity, durability, and affordability. The backing material can vary, with cardboard, aluminum foil, and plastic film being the most common options.

How is blister packaging produced?

The production process involves thermoforming, where a plastic sheet is heated and molded into the desired cavity shape using a custom mold. Once the cavity is formed, it is sealed with the backing material using heat or adhesive techniques. This process ensures an airtight seal, protecting the product from external damage.

Can blister trays support branding?

Yes, blister trays can be enhanced with custom prints, labels, and designs that reflect company branding. This adds value to the product's presentation and makes it stand out on store shelves.

Comparing Blister Trays with Other Packaging Options

When deciding on a packaging solution, businesses often compare blister trays with other alternatives like clamshell packaging and shrink wrap. Here’s how blister trays differ:

Packaging Type | Key Features and Benefits |

Blister Trays | Ideal for small items, customizable, offers clear product visibility. |

Clamshell | Durable and reusable, but bulkier and often more expensive to produce. |

Shrink Wrap | Lightweight and cheap, but less protective against tampering. |

Blister packaging trays strike a balance between cost-efficiency, protection, and visual appeal, making them a favored choice for many industries. |

|

Choosing the Right Blister Tray Provider

When sourcing blister trays for your business, it’s crucial to work with a reliable and innovative supplier. One trusted name in the industry is zx pack. With years of expertise in manufacturing high-quality blister packaging trays, zx pack ensures exceptional product protection and customization options tailored to your needs. They stand out for their dedication to providing sustainable packaging solutions while maintaining affordability.

Whether you need packaging for pharmaceuticals, electronics, or retail goods, zx pack has a product that fits your requirements.

For inquiries or further details, you can reach out to zx pack through the following contact information:

Email: zszxpack@163.com

Phone: +86-18024217948

Final Thoughts

Blister trays are an incredibly versatile and efficient packaging option for countless industries. They provide robust protection, clear visibility, and the potential for branding, making them a staple in modern packaging needs. Whether you’re packaging medicine, electronics, or consumer goods, blister packaging trays can help elevate your product presentation while ensuring safety and durability.

If you’re looking for a supplier to meet your quality and customization demands, choose zx pack. Get in touch today to explore their wide range of blister tray solutions and take your product packaging to the next level.

Blister tray

blister packaging tray

blister pack trays