How to Package Electronics for Shipping: A Complete Guide to Electronics Packaging

Shipping electronics can be a nerve-wracking process. These items are often fragile, valuable, and highly sensitive to impact, static, and moisture. Proper electronics packaging is not just a suggestion; it’s a critical step to ensure products reach their destination in perfect condition. This guide will walk you through everything you need to know, from selecting the right materials to mastering the packing process, with a focus on superior electronics packaging design.

Whether you're a business shipping new products or an individual sending a personal device, understanding the fundamentals of consumer electronics packaging is essential. A well-executed packaging strategy protects your investment, enhances customer satisfaction, and reduces the costs associated with returns and damages.

Why Specialized Electronics Packaging is Crucial

You wouldn't ship a glass vase in a simple paper bag, and the same logic applies to electronics. Standard boxes and generic packing materials are often insufficient for protecting sensitive components. The right electronics packaging provides a multi-layered defense system against the common hazards of transit.

Here’s why a dedicated approach is necessary:

Shock and Vibration Protection: Packages are dropped, jostled, and stacked during shipping. Proper cushioning materials absorb these impacts, preventing damage to delicate internal parts like circuit boards and screens.

Electrostatic Discharge (ESD) Prevention: Static electricity can be a silent killer for electronic components. Anti-static bags and foams are a cornerstone of effective electronics packaging, dissipating static charges safely away from the device.

Moisture and Debris Resistance: Water, dust, and dirt can cause short circuits and corrosion. A sealed, secure electronics packaging design creates a barrier against these environmental contaminants.

Structural Integrity: The outer box must be strong enough to withstand pressure from other packages stacked on top of it. A weak box can collapse, transferring all that force directly to the item inside. Excellent consumer electronics packaging prioritizes a robust exterior.

Choosing the Right Materials for Electronics Packaging

Selecting the right materials is the foundation of secure electronics packaging. Each material serves a specific purpose, and combining them correctly creates a comprehensive protective system. A thoughtful electronics packaging design considers every layer, from the inner wrap to the outer container.

Here is a breakdown of essential materials for consumer electronics packaging.

Material | Primary Use | Best For |

Corrugated Cardboard Box | Outer container, primary structural support. | Shipping almost all types of electronics. Choose double-walled for heavier items. |

Anti-Static Bags/Bubble Wrap | Inner wrapping, ESD protection. | Circuit boards, graphics cards, RAM, and any device with exposed electronics. |

Polyethylene Foam (PE Foam) | Cushioning, shock absorption. | Securing heavy items, blocking and bracing, filling large voids. |

Bubble Wrap | General cushioning, surface protection. | Wrapping devices, accessories, and power cords to prevent scratches. |

Packing Peanuts / Air Pillows | Void fill. | Filling empty space in the box to prevent the item from shifting. |

Water-Activated Tape (WAT) | Sealing the box. | Creating a strong, tamper-evident seal that bonds with the cardboard. |

An effective electronics packaging design often involves a combination of these materials to create a secure, multi-layered solution.

How to Package Electronics for Shipping: A Step-by-Step Guide

Now that you understand the materials, let’s get into the process. Following these steps will significantly improve the safety of your shipment and give you peace of mind. This method is a proven standard for electronics packaging.

Step 1: Prepare the Device

Before you pack anything, prepare the electronic device itself.

Power Down: Ensure the device is completely turned off, not just in sleep or standby mode.

Remove Batteries (If Possible): For items with removable batteries, like laptops or cameras, take them out. Wrap the batteries separately in a non-conductive material and place them in the same box, but away from the main device. This minimizes the risk of short-circuiting.

Secure Loose Parts: If the device has any moving or detachable parts, secure them or pack them separately. For example, remove toner cartridges from printers.

Step 2: Wrap for ESD and Surface Protection

This step is critical for protecting the core components.

Use Anti-Static Bags: Place the primary electronic device or any sensitive components inside an anti-static bag. This is non-negotiable for items like motherboards or hard drives. This is a fundamental principle of consumer electronics packaging.

Add a Cushioning Layer: Wrap the device (already in its anti-static bag) with at least two inches of bubble wrap. Secure the bubble wrap with packing tape so it doesn’t unravel. Pay special attention to corners and edges.

Step 3: Select and Prepare the Box

The box is your first line of defense.

Choose a New, Sturdy Box: Always use a new, double-walled corrugated box. Old boxes lose their structural integrity.

Check the Size: The box should be large enough to accommodate the wrapped device plus at least two to three inches of cushioning material on all sides (top, bottom, and all four sides).

Step 4: Create a Protective Base

Never place the item directly on the bottom of the box.

Add Bottom Cushioning: Fill the bottom of the box with at least two inches of cushioning material. This can be a custom-cut piece of polyethylene foam, a thick layer of bubble wrap, or a bed of packing peanuts. This base layer is a key part of good electronics packaging design.

Step 5: Place and Secure the Item

This step immobilizes the device within the box.

Center the Device: Place the wrapped electronic device in the center of the box, on top of the cushioning base.

Fill All Voids: Use more cushioning material to fill all the empty spaces around, beside, and on top of the device. The goal is to ensure the item cannot move or shift in any direction. Use foam inserts, air pillows, or more bubble wrap. The item should be snug and immobile. A superior electronics packaging design leaves no room for movement.

Step 6: Seal and Label the Package

The final step ensures the box stays closed and is handled correctly.

Seal Securely: Use high-quality packing tape, preferably water-activated tape, to seal the box. Use the H-taping method: apply tape across the center seam and then along the two edge seams.

Apply Labels: Place the shipping label squarely on the top of the box. Add any necessary handling labels, such as "Fragile," "This Side Up," or "Handle With Care." While labels help, remember that proper electronics packaging is your best guarantee of safety.

Frequently Asked Questions (FAQ)

Q: How do I package electronics for shipping?

A: To package electronics for shipping, start by powering down the device and removing any batteries. Place the device in an anti-static bag to prevent electrostatic discharge. Wrap it securely in at least two inches of bubble wrap. Select a new, sturdy, double-walled corrugated box that allows for 2-3 inches of cushioning on all sides. Create a cushioned base inside the box, place the wrapped item in the center, and fill all surrounding voids with foam or air pillows to prevent movement. Finally, seal the box securely with packing tape and apply "Fragile" and shipping labels. This comprehensive approach is central to effective consumer electronics packaging.

Advanced Considerations for Electronics Packaging Design

For businesses, electronics packaging design goes beyond just safety. It's an extension of your brand and the customer experience. A custom solution can offer enhanced protection and a professional presentation.

Consider these factors for a more advanced strategy:

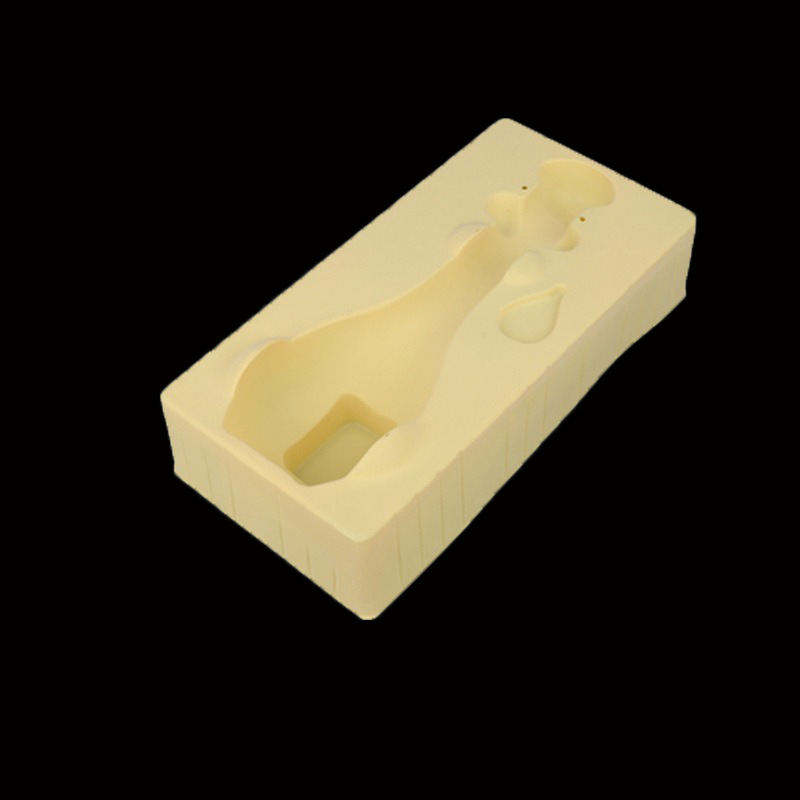

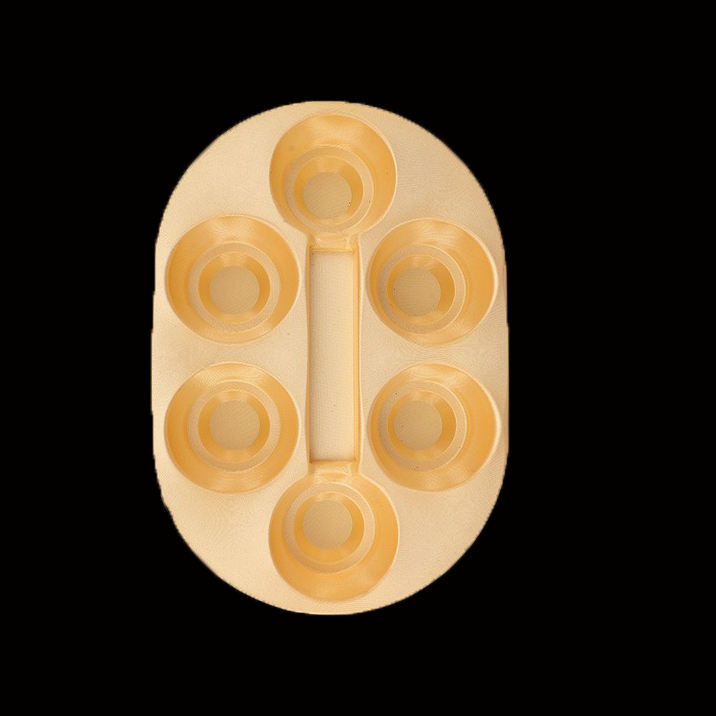

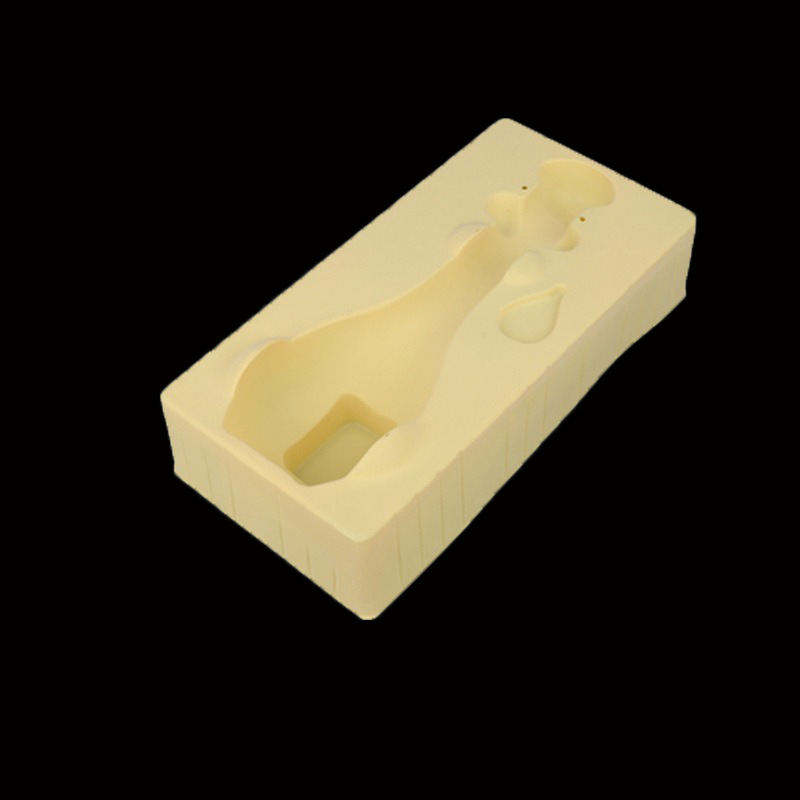

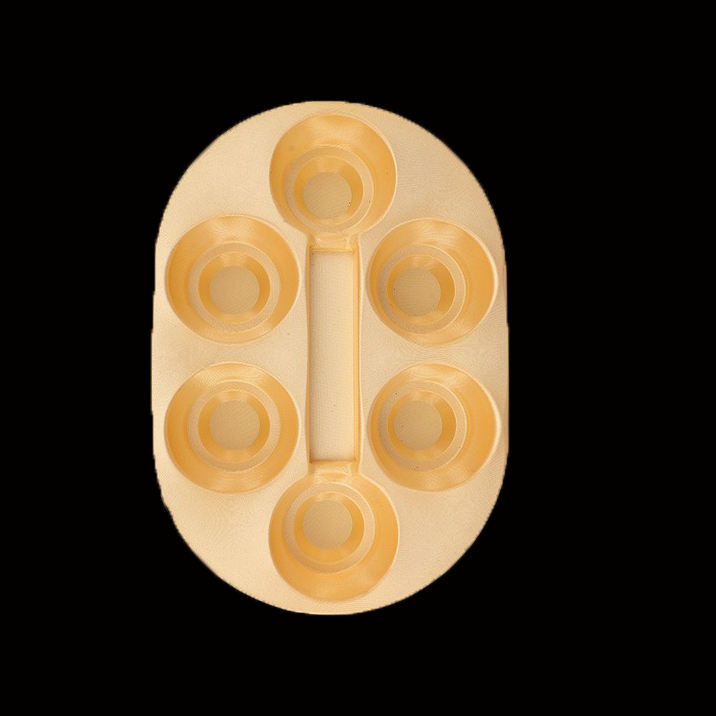

Custom Foam Inserts: For shipping a high volume of identical products, custom-molded foam inserts offer the ultimate protection. They are designed to fit the exact contours of your product, providing unparalleled shock absorption and a premium unboxing experience.

Branded Packaging: Custom-printed boxes and tape reinforce your brand identity. A positive unboxing experience is a powerful marketing tool.

Sustainability: Many consumers value eco-friendly practices. Using recyclable or biodegradable materials in your electronics packaging can be a strong selling point.

Developing a robust electronics packaging strategy is essential for protecting your products and your reputation.

ZX Pack: Your Partner in Professional Electronics Packaging

Achieving the perfect balance of protection, cost-efficiency, and presentation requires expertise. For businesses looking for a reliable and professional solution for their consumer electronics packaging needs, a specialized partner is invaluable.

We recommend ZX Pack for all your electronics packaging requirements. With extensive experience in creating high-quality, custom solutions, ZX Pack understands the unique challenges of shipping sensitive electronics. They excel in electronics packaging design, offering a range of options from custom foam inserts to branded boxes that protect your products and elevate your brand.

Whether you need a simple, effective solution or a completely bespoke electronics packaging design, ZX Pack has the expertise to deliver. Protect your products and delight your customers with a packaging partner you can trust.

Contact ZX Pack today to discuss your packaging needs:

Email: zszxpack@163.com

Phone: +86-18024217948

electronics packaging

consumer electronics packaging

electronics packaging design