In manufacturing and retail, product presentation and protection are paramount. How you package your items can significantly impact customer perception, supply chain efficiency, and your bottom line. Among the most versatile and effective solutions is plastic tray packaging. This method is especially crucial for complex assortments like hardware packages, where organization and security are key.

A well-designed plastic tray does more than just hold items; it organizes, protects, and showcases them. Whether you're bundling screws, bolts, and nuts or delicate electronic components, the right packaging prevents damage and provides a professional unboxing experience. This guide will explore the world of plastic tray packaging, its applications, and why it is the superior choice for hardware packages and other products. We will look at the materials, benefits, and customization options that make this packaging solution a staple across industries.

What is a Plastic Tray Used For?

A plastic tray is a highly versatile packaging solution used across numerous sectors. Its primary function is to securely hold, organize, and protect products during shipping, handling, and display. Unlike a simple box or bag, a plastic tray is often custom-molded to fit the specific shape and size of the items it contains.

Common uses for a plastic tray include:

Organizing Small Components: For products with multiple small parts, like hardware packages or electronic kits, a plastic tray with custom compartments is essential. It keeps items separated, preventing them from mixing or getting lost.

Protecting Fragile Items: Delicate electronics, medical devices, and glass components are susceptible to damage from impact and vibration. Plastic tray packaging provides a cushioned and secure enclosure, minimizing movement and absorbing shock.

Streamlining Assembly Lines: In manufacturing, trays are used to transport components in an organized manner. This makes the assembly process faster and more efficient, as workers can easily access the parts they need.

Enhancing Retail Display: A clear plastic insert allows customers to see the product clearly while keeping it secure. This improves shelf appeal and helps consumers understand what they are buying, which is particularly useful for complex hardware packages.

The adaptability of plastic tray packaging makes it a go-to solution for industries ranging from automotive and electronics to food and cosmetics.

Understanding Hardware Packages

So, what exactly constitutes a hardware package? A hardware package is a collection of small hardware components sold together as a single unit. These kits are assembled for a specific purpose, such as furniture assembly, equipment repair, or a DIY project.

Examples of items found in hardware packages include:

Screws, nuts, bolts, and washers Brackets and fasteners Wall anchors Small tools like Allen keys Specialized mounting components

The challenge with hardware packages is keeping these numerous small pieces organized and accounted for. Without proper packaging, items can easily get mixed up, lost, or damaged. This is where the synergy between a hardware package and plastic tray packaging becomes clear. A custom-molded plastic tray ensures every single screw and bolt has its designated spot, offering an unmatched level of organization and protection.

Why Plastic Tray Packaging is Ideal for Hardware

Using a generic bag for a hardware package can lead to a frustrating experience for the end-user, who has to sort through a jumble of parts. Plastic tray packaging solves this problem and offers several other distinct advantages.

Superior Organization

The most significant benefit is organization. A custom plastic tray features individual cavities for each component. This layout not only prevents parts from mixing but can also guide the user through an assembly process. By arranging items in a logical sequence, the packaging itself becomes part of the instruction manual.

Enhanced Product Protection

Hardware items, while durable, can be damaged. Threads on screws can be stripped, and delicate finishes can be scratched. A thermoformed plastic tray immobilizes each part, preventing them from colliding during transit. This ensures the products arrive in perfect condition, reducing returns and improving customer satisfaction.

Improved Professional Presentation

First impressions matter. A neatly organized hardware package in a custom plastic tray conveys quality and attention to detail. It elevates the perceived value of the product compared to items loosely packed in a bag or box. For brands looking to build a premium reputation, high-quality plastic tray packaging is a smart investment.

Efficiency in Kitting and Assembly

For manufacturers, plastic tray packaging streamlines the kitting process. Workers can quickly and accurately place each component into its designated cavity, reducing errors and increasing throughput. The structured layout of the plastic tray makes inventory counts and quality checks simpler and faster.

Types of Materials Used in Plastic Tray Packaging

The effectiveness of a plastic tray often comes down to the material used. The choice of plastic depends on the specific requirements of the product, such as the level of protection needed, cost considerations, and whether the product needs to be visible.

Material | Key Characteristics | Common Applications |

PET (Polyethylene Terephthalate) | High clarity, durable, good barrier against moisture and gas. | Food trays, retail packaging, hardware packages. |

PVC (Polyvinyl Chloride) | Rigid, durable, and cost-effective. Excellent for thermoforming. | Blister packs, clamshells, medical device trays. |

HIPS (High Impact Polystyrene) | Low cost, easy to form, available in various colors. | Food service trays, nursery flats, packaging for light items. |

PP (Polypropylene) | Lightweight, strong, high melting point. Resistant to chemicals. | Reusable containers, automotive parts trays. |

ESD (Electrostatic Discharge) | Formulated to prevent static buildup. | Trays for sensitive electronic components. |

For most hardware packages, PET is an excellent choice due to its clarity and durability. It allows customers to see the contents clearly while providing robust protection. A well-designed PET plastic tray offers the perfect balance of performance and aesthetics.

Customization: The Key to Effective Packaging

One of the greatest strengths of plastic tray packaging is its potential for customization. Off-the-shelf solutions rarely provide the perfect fit for unique products. A custom-designed plastic tray is tailored to the exact dimensions and shapes of your components.

Customization options include:

Cavity Design: The size, shape, and depth of each compartment can be precisely molded.

Material and Color: Choose the plastic that best suits your needs, with options for various colors to align with your brand.

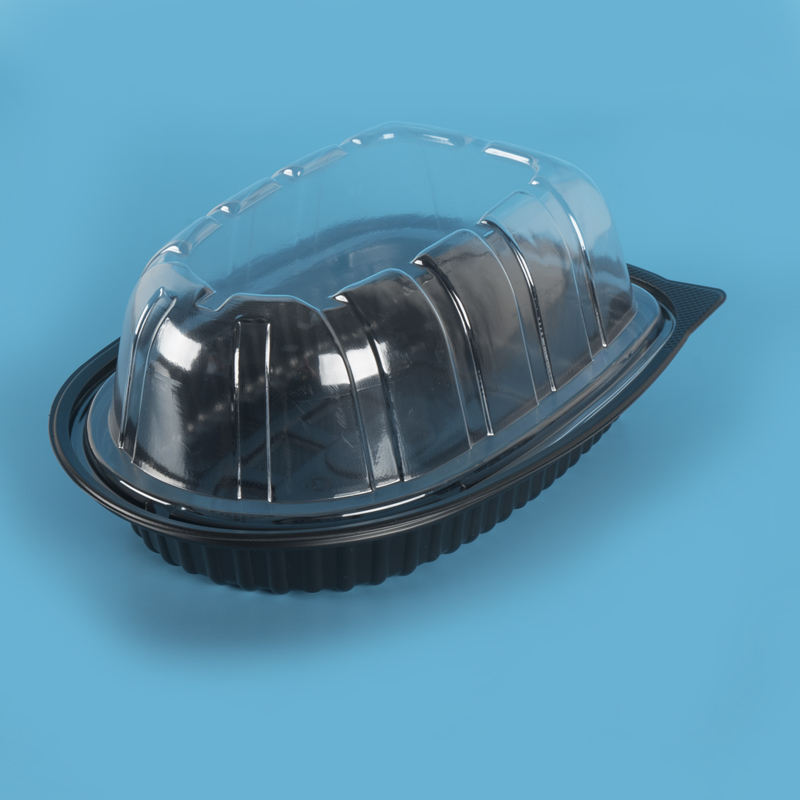

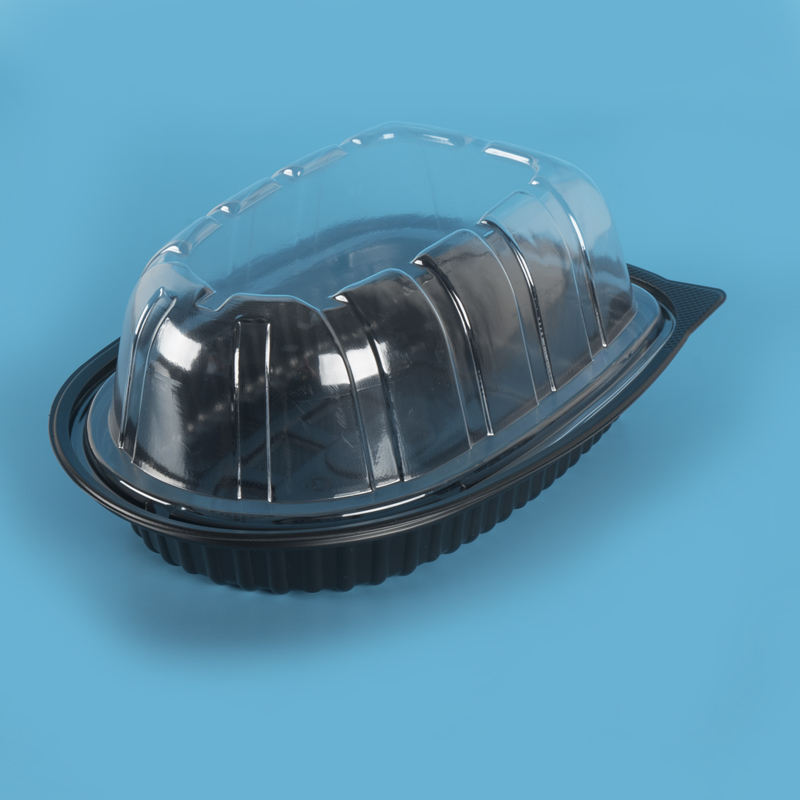

Lid and Sealing Options: Trays can be designed with matching lids or sealed with a film for a tamper-evident solution.

Branding: Logos and part numbers can be embossed directly into the plastic tray.

Investing in custom plastic tray packaging for your hardware packages ensures a perfect fit, maximum protection, and a premium presentation that strengthens your brand identity.

Frequently Asked Questions (FAQ)

What is a plastic tray used for?

A plastic tray is primarily used to hold, organize, and protect goods during shipping, storage, and display. It is particularly valuable for products with multiple small parts, such as electronics and hardware packages, as it keeps components separated and secure. Trays also protect fragile items from damage and improve efficiency in manufacturing assembly lines.

What is a hardware package?

A hardware package is a set of hardware components, like screws, nuts, bolts, and brackets, that are bundled and sold as a single kit. These packages are typically used for specific tasks, such as assembling furniture or installing equipment. Effective packaging, like a plastic tray, is crucial for keeping the various parts organized and intact.

The Clear Choice for Your Packaging Needs

Choosing the right packaging is a critical decision that affects everything from product safety to brand perception. For hardware packages and other multi-component products, plastic tray packaging stands out as the superior solution. Its ability to organize, protect, and display products is unmatched by other methods. A custom plastic tray delivers a professional unboxing experience, reduces product damage, and enhances efficiency throughout the supply chain.

When you need reliable and high-quality packaging solutions, consider a specialist who understands the nuances of custom design and manufacturing. For exceptional plastic tray packaging tailored to your unique requirements, we recommend casenl. Their expertise in creating custom trays for hardware packages and other industrial applications ensures you receive a product that meets your exact specifications.

To learn more about how casenl can elevate your packaging, contact them today.

Email: zszxpack@163.com

Phone: +86-18024217948

Plastic tray packaging

plastic tray

hardware packages