Everything You Need to Know About Blister Trays

Blister trays are an essential part of modern packaging solutions, offering versatility, durability, and efficiency. Made from various types of plastic, blister trays are widely used across multiple industries, from electronics to cosmetics. This article will explore everything about blister trays, including their uses, benefits, and the different types such as electronic plastic trays and cosmetic tray packaging. We will also provide insights into plastic tray packaging, addressing frequently asked questions, and conclude with a trusted recommendation for your packaging needs.

What is a Blister Tray?

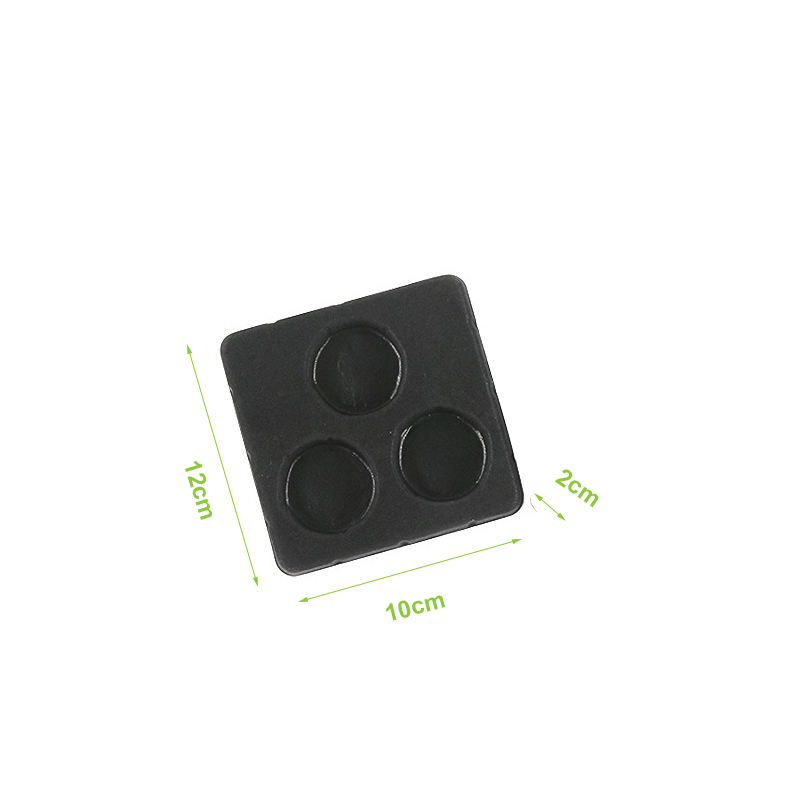

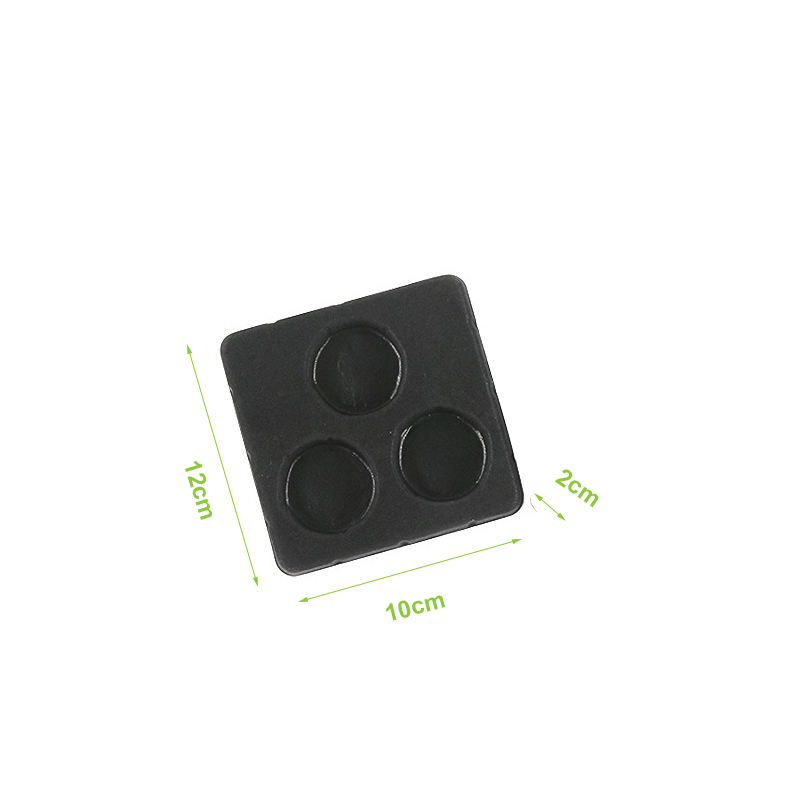

A blister tray is a type of plastic tray packaging made from molded plastic sheets. These trays are designed to securely hold and display items while protecting them from external elements such as dust, moisture, and impacts. Blister trays are commonly used in retail packaging because they allow consumers to see the product through the clear plastic while ensuring the product remains securely housed.

How Does a Blister Tray Work?

Blister trays are formed through a process called thermoforming. A plastic sheet is heated to a pliable temperature and then vacuum-formed over a mold to create the desired shape. Once cooled, the tray is trimmed to its final size. This process ensures that the tray perfectly fits the product it is intended to hold. The design flexibility of blister trays makes them suitable for items of all shapes and sizes.

Applications of Blister Trays

Blister trays have diverse applications across industries due to their functionality and customization options. Here are the primary sectors where blister trays are commonly used:

1. Electronic Plastic Tray Packaging

Blister trays are heavily used in the electronics industry due to their ability to securely house delicate and sensitive components. These trays are often referred to as electronic plastic trays and are designed to hold items like circuit boards, microchips, cables, and other small electronic parts. The trays not only prevent damage during transportation but also help organize parts for assembly processes.

2. Cosmetic Tray Packaging

For beauty and personal care products, blister trays play a key role in creating attractive and functional packaging. Cosmetic tray packaging is often used to hold items such as lipsticks, makeup palettes, skincare jars, and more. These trays can be customized to enhance the appearance of the product and align with the brand’s aesthetic. Clear plastic trays, in particular, are popular in this category as they allow the product to be prominently displayed.

3. Food and Pharmaceutical Packaging

Blister trays are also commonly used in the food and pharmaceutical industries. For pharmaceuticals, they are used to package pills, capsules, and other medical devices. The precise molding of the tray ensures that the contents are protected from contamination. Similarly, in the food industry, blister trays are used to package items like chocolates, candies, and single-serving meals.

Benefits of Using Blister Trays

Blister trays provide a range of benefits that make them an ideal choice for packaging. Below are some of the top advantages:

1. Protection

Blister trays provide excellent protection to the product. The molded plastic encases the item, shielding it from dust, dirt, moisture, and physical damage during transportation and storage.

2. Customization

One of the standout features of blister trays is their customization options. Whether you need an electronic plastic tray or cosmetic tray packaging, these trays can be molded to fit the exact dimensions of your product. You can even add brand logos, designs, or labels directly onto the tray.

3. Cost-Effectiveness

Blister trays are a cost-effective packaging solution. They use minimal material while providing maximum durability and functionality, making them affordable even for small businesses.

4. Eco-Friendliness

Modern blister trays can be made from recyclable and biodegradable materials, making them an environmentally friendly option. Companies that prioritize sustainability often look for eco-friendly plastic tray packaging solutions.

5. Enhanced Product Visibility

Blister trays, especially clear plastic trays, allow consumers to view the product without opening the package. This transparency increases consumer trust and encourages purchases.

6. Lightweight and Stackable

Plastic trays are lightweight, which reduces shipping costs. They are also stackable, making them easy to store and handle, especially for bulk packaging.

Types of Plastic Tray Packaging

Blister trays are not a one-size-fits-all solution. Depending on your needs, you may require specific types of plastic tray packaging. Below is an overview of the types available:

| Type of Tray | Common Uses |

| Electronic Plastic Tray | Holds small electronic parts such as circuit boards and cables, ensuring they remain organized and intact. |

| Cosmetic Tray Packaging | Designed for cosmetic products like makeup and skincare items, emphasizing beauty and functionality. |

| Insert Blister Trays | Used as separators or organizers within other packaging, ideal for products with multiple components. |

| Food Blister Trays | Designed for individual food servings, ensuring safety and freshness. |

| Medical Blister Trays | Used for pharmaceuticals like pills, medical instruments, and devices. |

Materials Used in Blister Tray Manufacturing

Blister trays are made from a variety of plastic materials, each chosen based on the specific requirements of the product being packaged. Some common materials include:

PVC (Polyvinyl Chloride) : Known for its affordability and durability, PVC is widely used for blister trays. It is rigid, transparent, and provides excellent protection.

PET (Polyethylene Terephthalate) : PET is a more eco-friendly option and is highly durable and recyclable.

PS (Polystyrene) : Polystyrene is lightweight and cost-effective, making it suitable for disposable blister trays.

BPA-Free Materials : For industries like food and cosmetics where safety is a priority, BPA-free plastics are often used. Each material comes with its unique set of characteristics, allowing manufacturers to choose one that aligns with their product's needs.

The Manufacturing Process of Blister Trays

The manufacturing of blister trays is a detailed but efficient process designed to meet precise specifications. Below is a step-by-step breakdown:

Design and Prototyping

The first step involves designing the tray’s mold based on the product’s dimensions and shape. A prototype is created to ensure the tray fits and functions correctly.

Thermoforming

The plastic sheet is heated and vacuum-formed over the prepared mold. This process shapes the tray into its final form.

Trimming and Finishing

Once the plastic has cooled, excess material is trimmed off to create the finished tray.

Quality Inspection

The final trays undergo a rigorous quality check to ensure they meet standards for durability, clarity, and functionality.

Frequently Asked Questions (FAQs)

1. What is the difference between blister packaging and clamshell packaging?

Blister trays are single molded trays that require a backing material like cardboard or plastic film, whereas clamshells are hinged two-part containers that enclose a product entirely.

2. Are blister trays recyclable?

Yes, blister trays made from PET or other recyclable plastics can often be recycled. However, the recyclability may vary depending on local recycling facilities.

3. Can blister trays be customized?

Absolutely! Blister trays can be custom-designed to fit the shape, size, and aesthetics of your product.

4. Are there eco-friendly options available for blister trays?

Yes, many manufacturers now offer eco-friendly options made from recycled or biodegradable materials to reduce environmental impact.

5. How durable are blister trays?

Blister trays are highly durable. They are designed to protect products from physical damage, moisture, and contaminants during handling and transport.

Why Choose Blister Trays for Your Packaging Needs?

Blister trays are one of the most versatile and effective solutions for packaging a wide range of products. Their ability to enhance product visibility, protect contents, and reduce shipping costs makes them a popular choice among manufacturers and retailers. Whether you’re looking for electronic plastic trays to secure delicate components or cosmetic tray packaging to elevate your brand’s presentation, blister trays are a reliable and innovative solution.

Your Trusted Blister Tray Manufacturer

If you’re searching for a trusted partner to meet your plastic tray packaging needs, ZSZX Pack is your go-to source. With years of expertise, ZSZX Pack specializes in designing and producing high-quality blister trays tailored to different industries. Whether you need electronic plastic trays, cosmetic tray packaging, or anything in between, they deliver exceptional results.

For inquiries, contact ZSZX Pack at:

Email: zszxpack@163.com

Phone: +86-13560620448

Invest in durable, customizable, and affordable blister trays with ZSZX Pack to elevate your product packaging to the next level!