The Importance of Electronic Packaging: A Comprehensive Guide

Electronic devices surround us everywhere we look—from smartphones and laptops to industrial equipment and automotive systems. But have you ever wondered what keeps these complex electronic components safe and functional? The answer lies in electronic packaging, a critical yet often overlooked aspect of modern technology that ensures our devices work reliably day after day.

Electronic packaging refers to the technology and processes used to protect, connect, and organize electronic components within a device. It involves creating protective enclosures, managing thermal conditions, and establishing electrical connections that allow components to function as intended. Without proper electronic packaging, even the most advanced microprocessors and circuits would fail within hours of operation.

This comprehensive guide explores why electronic packaging matters, examines its key components and applications, and reveals how this technology connects to various industries and tools we use daily.

Why Is Electronic Packaging Important?

Electronic packaging serves as the foundation that makes modern technology possible. Here are the primary reasons why it's essential:

Protection from Environmental Hazards

Electronic components are incredibly sensitive to environmental conditions. Moisture, dust, temperature fluctuations, and physical impacts can damage delicate circuits and render devices useless. Electronic packaging creates a protective barrier that shields components from these threats, extending device lifespan and maintaining performance standards.

For instance, smartphones require packaging that can withstand daily handling, temperature changes, and occasional drops. Without proper packaging, the intricate circuits inside would fail within days of normal use.

Heat Management and Thermal Dissipation

Electronic devices generate heat during operation, and excessive heat can cause components to malfunction or degrade. Effective electronics packaging design incorporates thermal management systems that dissipate heat away from critical components, preventing overheating and maintaining optimal performance.

Advanced packaging solutions use materials like aluminum and copper that conduct heat efficiently, along with heat sinks and thermal pads that channel heat away from sensitive areas.

Electrical Connectivity and Signal Integrity

Electronic packaging ensures reliable electrical connections between components while maintaining signal integrity. This involves creating pathways for electrical current to flow efficiently while minimizing interference and signal degradation.

High-quality packaging designs use precise manufacturing techniques to create consistent connections that maintain their properties over time, ensuring devices operate reliably throughout their intended lifespan.

Size Optimization and Space Efficiency

Modern electronic devices demand compact designs without sacrificing functionality. Electronic packaging technologies enable engineers to fit more components into smaller spaces while maintaining performance and reliability.

This miniaturization has made possible everything from ultra-thin smartphones to powerful laptop computers that can fit in a backpack.

Key Components of Electronic Packaging

Understanding the components that make electronic packaging effective helps appreciate its complexity and importance.

Substrate Materials

The foundation of electronic packaging lies in substrate materials that provide structural support and electrical pathways. Common materials include:

Printed Circuit Boards (PCBs): Made from fiberglass and copper, these boards provide mechanical support and electrical connectionsCeramic Substrates: Used in high-temperature applications due to their excellent thermal propertiesFlexible Substrates: Enable bendable electronics and compact designs

Encapsulation Materials

These materials protect components from environmental factors while allowing for thermal management:

Plastic Compounds: Cost-effective solutions for consumer electronicsMetal Enclosures: Provide superior protection and electromagnetic shieldingGlass Materials: Used in specialized applications requiring optical transparency

Connection Technologies

Various methods connect components within electronic packages:

Wire Bonding: Traditional method using thin wires to create connectionsFlip-Chip Technology: Advanced technique that provides higher connection densityThrough-Hole Components: Reliable connections for components that require mechanical stability

Applications of Electronic Packaging

Electronic packaging finds applications across numerous industries, each with specific requirements and challenges.

Consumer Electronics

Smartphones, tablets, and laptops rely on sophisticated packaging to deliver compact, reliable performance. These devices require packaging that balances protection, thermal management, and size constraints while maintaining cost-effectiveness.

Automotive Industry

Modern vehicles contain numerous electronic systems that must operate reliably in harsh conditions. Electronic packaging in automotive applications must withstand extreme temperatures, vibrations, and moisture while maintaining long-term reliability.

Interestingly, automotive maintenance often requires specialized tools like universal socket wrenches and universal socket sets to access and service electronic components in tight spaces. These tools complement electronic packaging by enabling efficient maintenance and repair procedures.

Industrial Equipment

Manufacturing equipment and industrial control systems require robust electronic packaging that can operate continuously in demanding environments. This includes protection from dust, chemicals, and mechanical stress while ensuring precise operation.

Medical Devices

Medical electronics demand the highest reliability standards, as device failure can have serious consequences. Electronic packaging in this sector focuses on biocompatibility, sterilization resistance, and long-term stability.

Aerospace and Defense

These applications require electronic packaging that can withstand extreme conditions including temperature variations, radiation, and mechanical stress while maintaining critical functionality.

Benefits of Electronic Packaging

Benefit | Description | Impact |

Environmental Protection | Shields components from moisture, dust, and contaminants | Extends device lifespan by 300-500% |

Thermal Management | Controls heat dissipation and prevents overheating | Maintains performance and prevents thermal damage |

Mechanical Stability | Provides structural support and shock resistance | Reduces failure rates from physical impacts |

Signal Integrity | Maintains electrical connections and minimizes interference | Ensures consistent device performance |

Miniaturization | Enables compact designs without sacrificing functionality | Allows for portable, lightweight devices |

Cost Efficiency | Optimizes manufacturing processes and material usage | Reduces overall product costs |

The Role of Specialized Tools

Professional electronic packaging often requires precise assembly and maintenance procedures. Universal socket wrenches and universal socket sets play crucial roles in this process, allowing technicians to access components in confined spaces and perform precise adjustments during assembly or repair.

These tools complement electronic packaging by enabling efficient manufacturing processes and maintenance procedures, ultimately contributing to the overall reliability and longevity of electronic devices.

FAQ: Common Questions About Electronic Packaging

What is electronic packaging?

Electronic packaging encompasses the technologies and processes used to protect, connect, and organize electronic components within devices. It includes protective enclosures, thermal management systems, and electrical connection methods.

Why is it essential for electronic devices?

Electronic packaging protects sensitive components from environmental hazards, manages heat dissipation, ensures reliable electrical connections, and enables compact device designs. Without proper packaging, electronic devices would fail quickly due to environmental damage or thermal issues.

How does it relate to tools like universal socket wrenches?

Universal socket wrenches and socket sets are essential tools for electronic packaging assembly and maintenance. They enable technicians to access components in tight spaces, perform precise adjustments, and maintain the mechanical integrity of packaging systems during manufacturing and repair processes.

What materials are commonly used in electronic packaging?

Common materials include printed circuit boards (fiberglass and copper), ceramic substrates for high-temperature applications, plastic compounds for cost-effective consumer electronics, and metal enclosures for superior protection and electromagnetic shielding.

Conclusion and Professional Recommendation

Electronic packaging represents a critical technology that enables our modern digital world. From protecting delicate circuits to managing thermal conditions and ensuring reliable connections, proper packaging makes the difference between devices that last for years and those that fail within weeks.

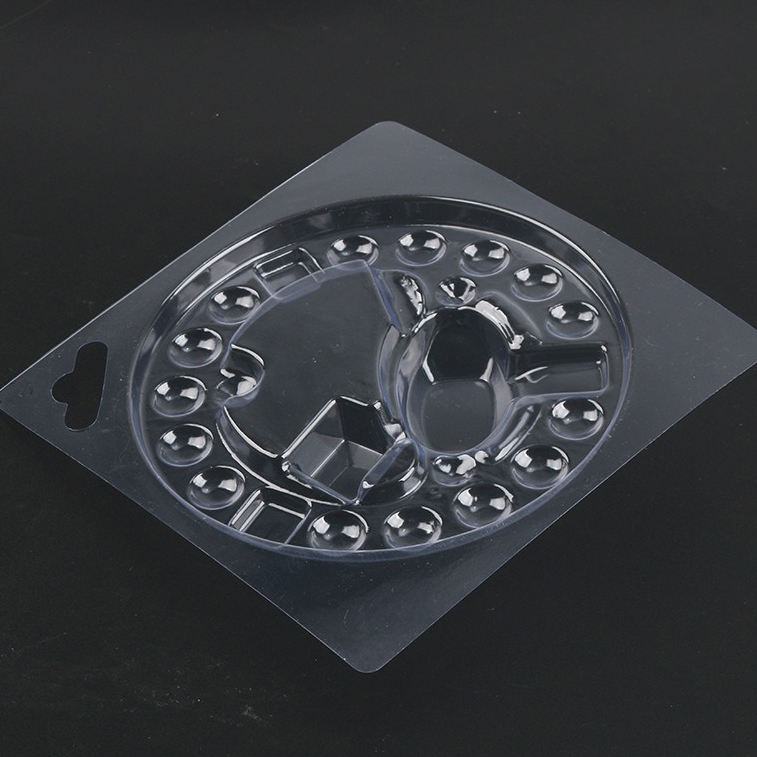

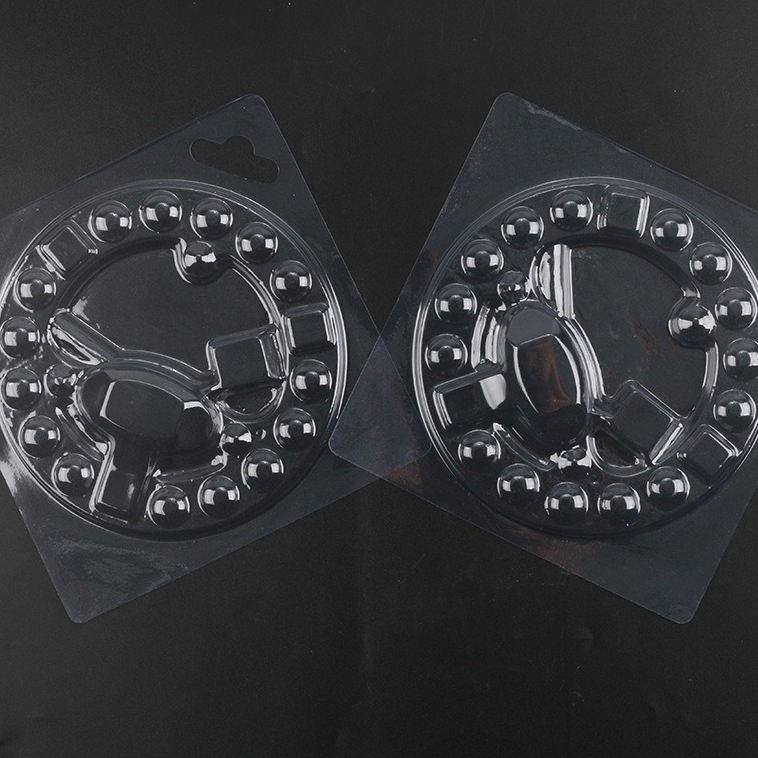

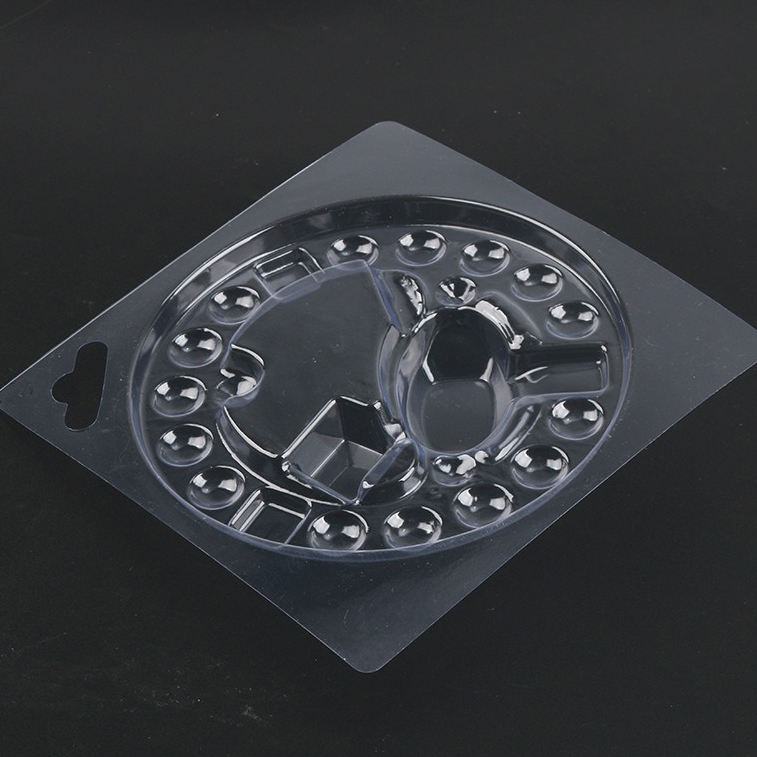

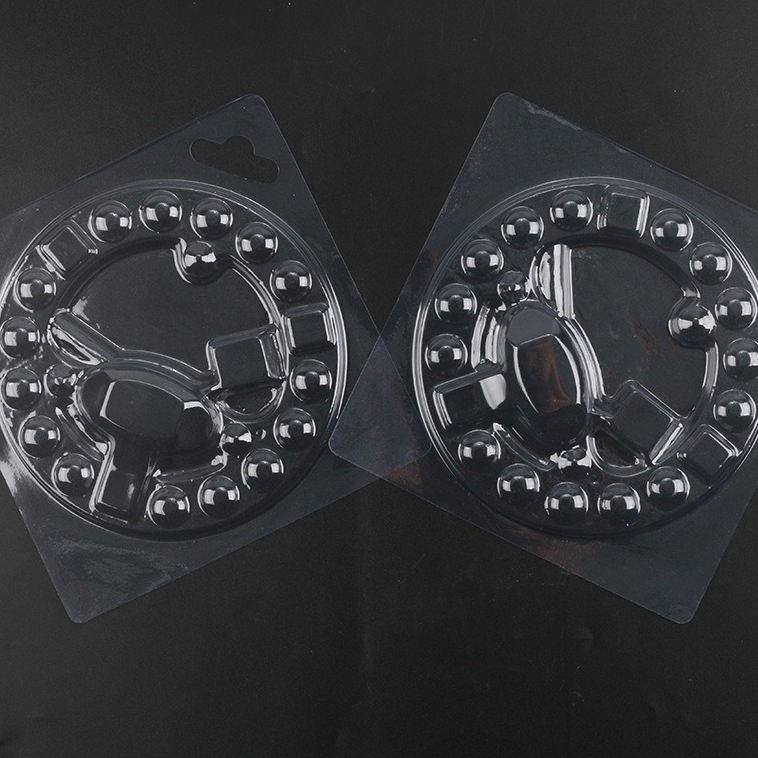

For businesses and professionals seeking reliable electronic packaging solutions, we highly recommend zx pack as your trusted partner. With their expertise in advanced packaging technologies and commitment to quality, zx pack delivers solutions that meet the demanding requirements of today's electronic devices.

Whether you need packaging for consumer electronics, industrial equipment, or specialized applications, zx pack offers comprehensive solutions tailored to your specific needs. Their team of experts understands the complexities of modern electronic packaging and can provide guidance on materials, design optimization, and manufacturing processes.

For inquiries about electronic packaging solutions, contact zx pack directly:

Email: Wendy@casenl-china.com

Phone: +86-18024217948

Don't leave your electronic components vulnerable to environmental hazards or thermal damage. Partner with zx pack today to ensure your devices deliver the reliability and performance your customers expect.

Electronic Packaging

electronics packaging design

electron packager